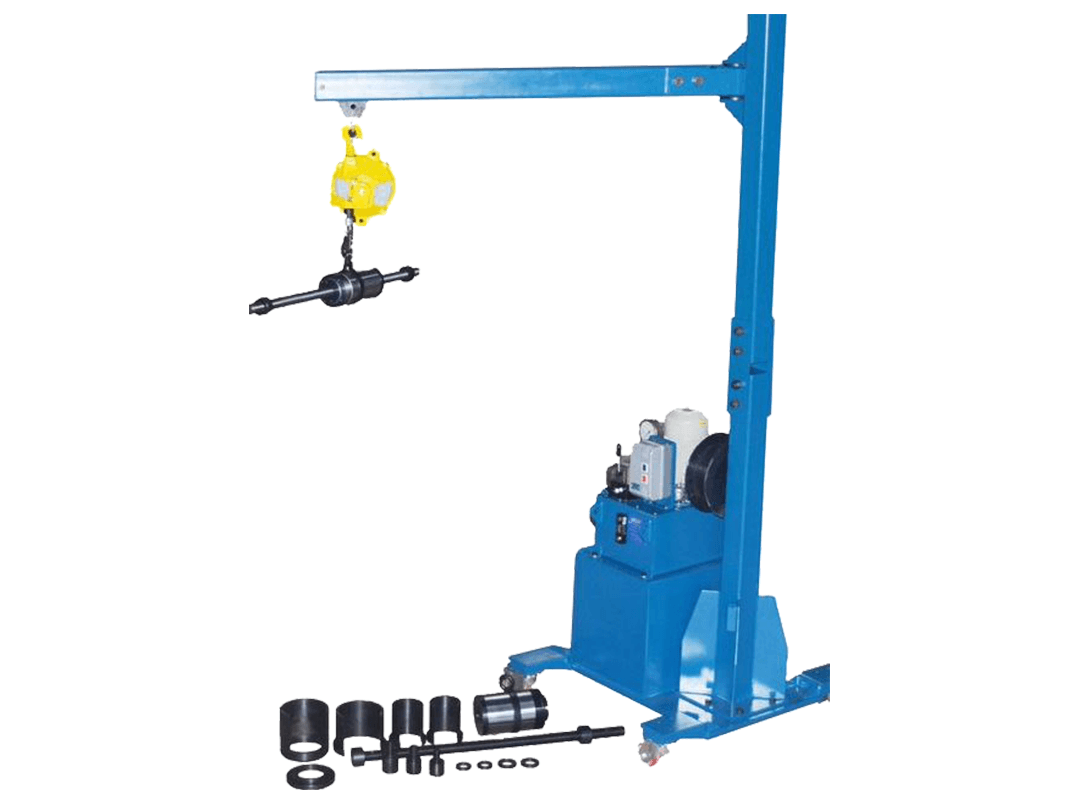

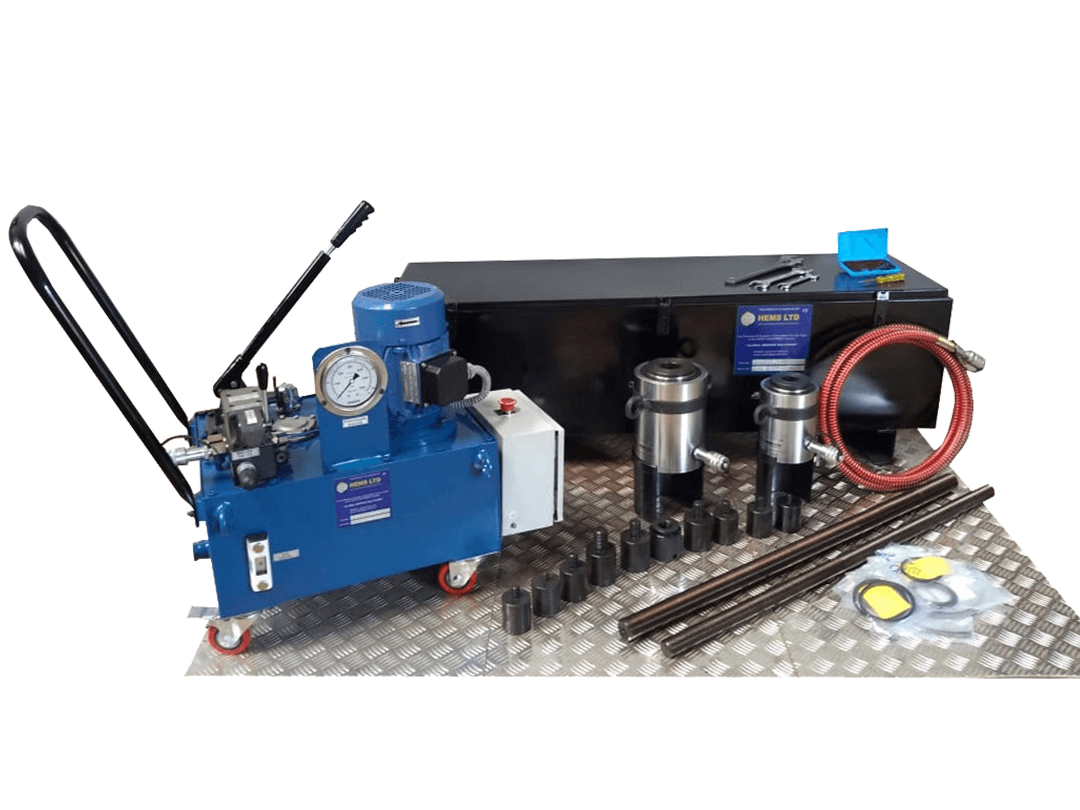

Under Carriage Repair

Hydraulic Pin Puller

Models: HE PP 30/50, HE PP 100, HE PP 150, HE PP 200

HEMS Hydraulic Pin Puller allows precise, hands-free removal of pins and fitted bushings. Each pin puller kit is supplied with one of three control options:

Why Choose Our Hydraulic Pin Puller?

Engineered for professionals who demand reliability, efficiency, and precision in their heavy machinery maintenance operations.

Precision Engineering

Designed with precision components for accurate track pin removal and installation, ensuring optimal performance every time.

Built to Last

Constructed with high-grade materials and robust engineering to withstand the demands of heavy-duty industrial applications.

Efficient Operation

Streamlined design reduces operation time and effort, making field service and shop repairs faster and more efficient.